+1 225-267-7656

Effective action necessitates accurate information.

24/7/365

Subject Matter Experts

Value Proposition

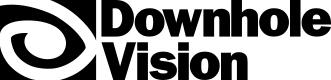

Insight Video

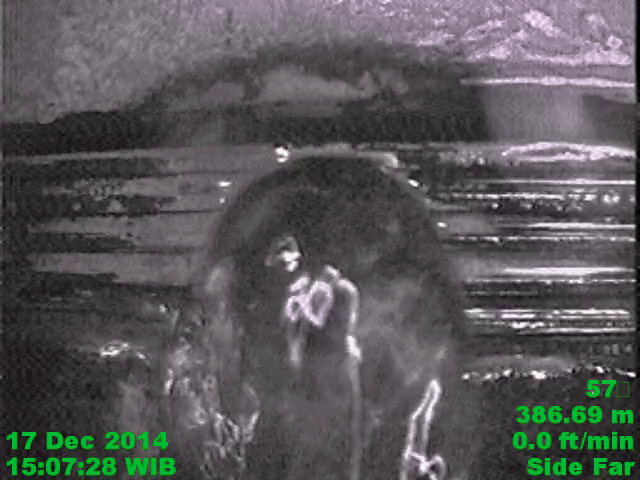

Insight MemoryHD Monitoring Well

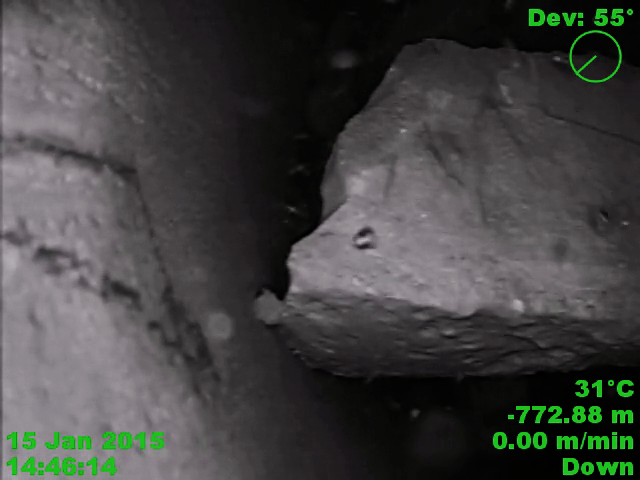

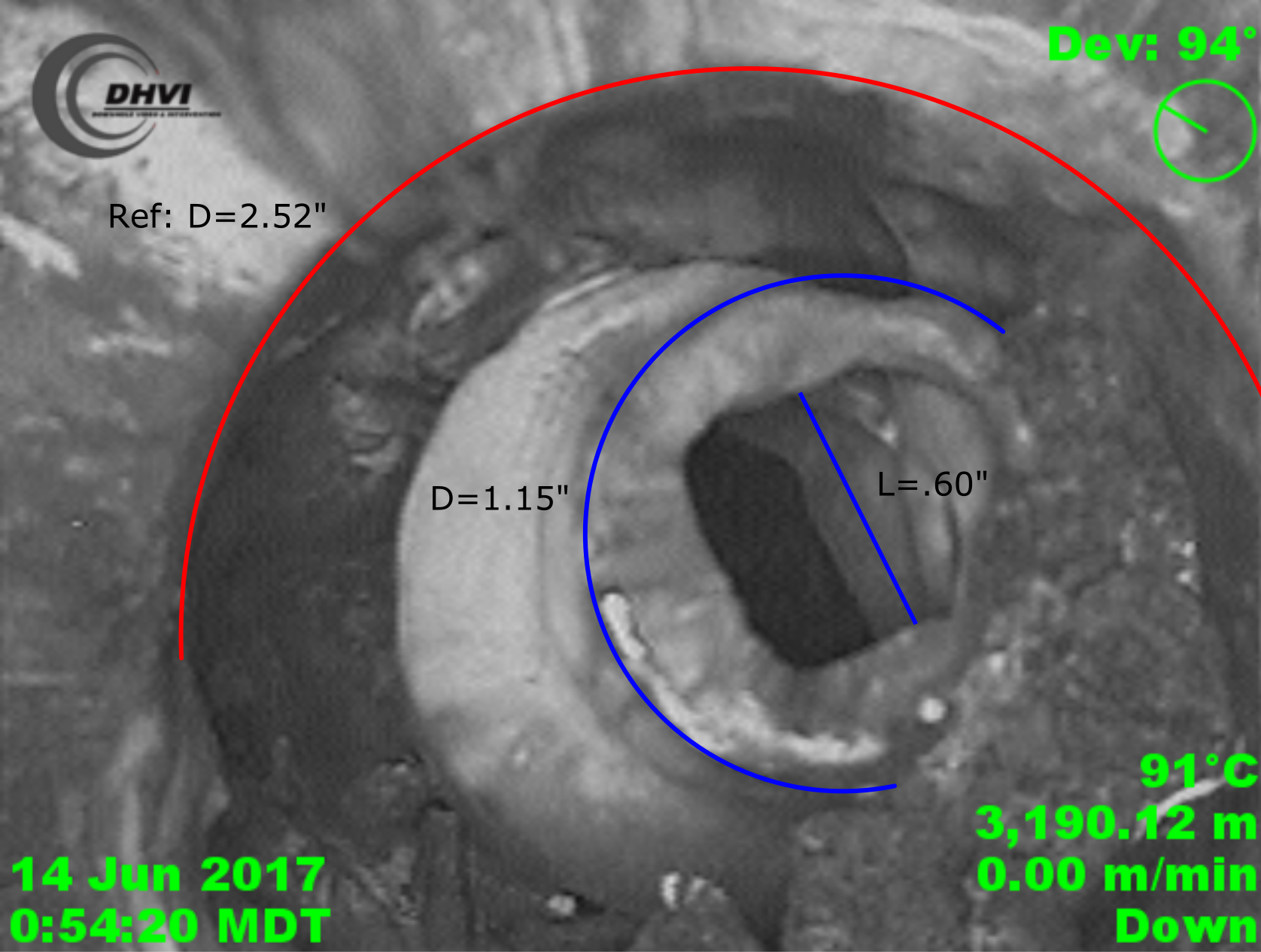

Insight MemoryHD Flapper Inspection

Frequently Asked Questions

What Insight system is best suited to my well issue? (Memory vs. SRO)

Our most economic solution is the InsightMemory series. This HD color well imaging system provides full motion video of the well environment and is best suited for tubing and casing diameters of 7” and smaller for optimal lighting. However, being a memory based-system, the visual well log is not observed in real time. In cases of a known well obstruction at a particular depth or to investigate a specific mechanical function (e.g. flapper valve operation) this may be the most suitable solution.

However, if the nature of the visual well log is exploratory and / or real-time observation of the well condition is required, then use of a realtime / Surface Read-Out (SRO) system indicated. Fishing operations or complex well failure events typically require operator interaction and control over lighting, camera positioning, camera rotation, active camera selection and more, all of which are only available on realtime systems.

For challenging environments such as flowing injections wells, higher bandwidth options such as fiber may be the best option.

Is well preparation necessary?

Visual well logging performs best in transparent mediums. Suspended solids and high oil cut environments can introduce unwanted artifacts in the visual images/video captured. For best results in an oil well environment, preparation is often necessary.

For gas wells, water wells or geothermal wells, minimal initial preparation is typically required.

For idle wells that have been dormant for extended periods, it should be expected to have poorer image quality in an oil pad at the uppermost interval of logging. Furthermore, sediment can be loosened from the wellbore walls during entry, and gravity will naturally encourage this sediment to fall downhole during logging, possibly impacting image clarity. Sometimes, a scraper run and circulation is helpful. Other times, shutting the well in for ~24 hours may be the key.

Click here for in-depth discussion of well preparation procedures.

Are Insight e-line system compatible with all wirelines?

That’s our goal. As with any logging technology, telemetry performance depends on wireline bandwidth and an electrically clean environment. High line resistance or capacitance will reduce bandwidth. (Insight works best below 125 Ω, but under the right circumstances can tolerate loop resistances as high as 300 Ω.) Small diameter, exceedingly long, or sour service (MP35N) lines all reduce bandwidth. So, given the choice between 20,000′ of 5/16″ line and 30,000′ of 7/32″ line, the former would offer better performance.

With respect to existing surface system integration, all we need is depth encoder output into our system (either directly from your quadrature encoder, from your depth measurement system, or from an encoder we can provide.) We utilize our own portable telemetry & power system, and require direct access to the wireline, preferably at the slip-ring connection, for real-time camera operations.

As a wireline service provider, can we utilize the Insight system for our customers?

Without question. In fact, that’s how our deep work (oil & gas) systems are typcially deployed. If required, we can provide an engineer to assist with running the tool.

If you are a service provider in need of a visual well log as part of a scope of work, we are more than happy to work with you. Our camera systems work on mono-conductor e-line, multi-conductor e-line, coax, fiber, slickline, e-slickline, conventional coiled tubing and e-coil.

Can other instruments be run with the camera?

Yes, but to have a downward view, the camera pretty well has to be at the end of the string…

With memory tools, integration can be as simple as just placing everything in the same tool string, minding the offsets, and correlating by time.

With real-time SRO things get a bit more complicated. Video benefits from using the most advanced, high bandwidth telemetry available. As such, it’s usually best if data from other instruments or sensors can be multiplexed into the camera’s telemetry. This has been done to pair cameras with calipers, external pressure and / or temperature sensors, salinity sensors, TDS sensors, CCLs, gamma sensors, and acoustic sensors, to name a few.

Where such integrations don’t already exist, a switching sub might be used. This approach works quite well with calipers, for instance, as it’s normal to monitor the camera while running downhole, and the calipers while running uphole. A similar approach can be used when using a less-advanced or electrically noisy tractor to deploy the tool, where logging while tractoring may not be an option.

What advantages does a color video have over black and white?

In many wells, very few. Color imaging can be beneficial in open hole or highly corroded environments. And, it’s sometimes surprising to see the colors that exist downhole. But, at the end of the day, you’re likely to see what you’re looking for with either; color can just sometimes make an issue easier to spot. Most of our equipment operates in HD color, while our legacy systems (Insight1.x and Insight2), and certain unflasked high temperature gear is standard definition B&W.

How quickly will I receive my visual well log data?

When operating in real-time mode, you will witness and help direct the log as it is being created. Dependent on available bandwidth, live streaming of data to stakeholders at remote sites can allow them to take part, as well. At the completion of the run, it’s typical to provide flash drive[s] containing a “hit list” of video clips of the most salient portions of the log, along with video[s] capturing the entire run.

If significant post-processing measurement or other analysis is being performed, this may take place after data is transmitted “back to the office” (either ours or yours) for future analysis. We have decades of experience with image processing and computer vision algorithms. Should you send a video to us, we may be able to apply filtering or other image processing techniques that markedly improve or clarify results.

What is the file format of the log data you provide?

Depending on the camera model and operating mode, it will produce either static .png files or H.264 / H.265 video. Numeric/textual data is captured as .csv / .tsv files, which can be easily imported into spreadsheet or well diagnostic software.

We also provide a freely-distributable Insight Viewer software package, which allows the user to quickly peruse image and video data, add annotations, export clips, and more.

Is any special hardware required for viewing the log data?

A computer running a reasonably current version of Windows, Linux or OS X is all that is required to run the Insight Viewer software. Alternatively, the still images, video and text files we produce can all be viewed on any of these operating systems using built-in native functionality.

What are the operational limits for the Insight system?

Standard oil & gas tools have a maximum operating pressure of at least 10k PSI / 680 bar and maximum tool temperature of at least 257 °F / 125 °C. Higher pressure (15k, 20k PSI) and higher temperature (150, 175, 200 °C) variants are also available.

What are the dimensions of the Insight instruments?

In general, most tools for oil & gas hold to 1.75″ OD at standard temperatures, or 2.125″ / 3.5″ when flasked. Shallow work and geothermal tools are typically 3.5″ OD.

The length of a toolstring will vary. Additional batteries, sensors, and inline centralizers will lengthen it considerably. Over-housing centralizers can be used when rig-up height is constrained.

What is Burst Mode?

From our very first model, all e-line cameras produced by Downhole Vision have contained hybrid memory / SRO functionality.

“Burst Mode” is a hybrid feature that allows the tool to capture full frame rate video and buffer it in the tool, sending it to the surface as wireline bandwidth permits. Multiple Burst Mode captures can be performed during a single run.

We utilize the Burst Mode feature when an interesting well dynamic or feature is observed and full frame rate, high quality video would aid visualization.

Can the Insight system be deployed in deviated or horizontal wells?

Yes. For deviated wells, it is best to work with the wireline service provider to construct a bottom hole assembly that allows the instrument to overcome long build sections or highly inclined completion intervals. Roller centralizers and / or a pump-down centralizer may be appropriate. For highly deviated or horizontal wellbores, Insight is deployable via tractor or coiled tubing.

Does the Insight system require centralization during a log?

Functionally no, but practically yes. At a minimum, we will usually deploy any Insight instrument assembly with a bottom, inline centralizer to protect the sapphire windows atthe bottom of the tool against collecting grime or coming into contact with low-side obstructions or well debris. Furthermore, centralization assures that the full periphery of the wellbore can be visualized, and provides an overall better quality log by eliminating cyclical bouncing. Running a second centralizer above the tool helps to increase stability, and is required in deviated wells to keep the tool parallel with the bore.

What image resolution can I expect from the Insight systems?

Insight1.5 / Insight2 capture SD resolution images at 640×480 pixels.

Insight3 and MemoryHD capture Full HD images at up to 1080p (1920×1080 pixels).

Shallow work systems are typically configured for Full HD or 4k resolution.